In an article entitled “Pico-litre Sample Introduction and Acoustic Levitation Systems for Time Resolved Protein Crystallography Experiments at XFELS”, published in Sensors and Transducers [Vol 214, issue 7, July 2017] , PolyPico’s acoustic dispensing technology was used to dispense the pico-litre slurries of crystals required for Time Resolved Protein Crystallography Experiments using X-ray Free Electron Lasers (XFEL) successfully.

“XFELs generate Light a billion times brighter than the sun. The application for this system will be to examine turn over in Beta lactamase proteins which is responsible for bacteria developing antibiotic resistance and therefore of significant importance to future world health. The system will allow for diffraction data to be collected before and after turnover allowing for a better understanding of the underling processes.

PolyPico produce a drop-on-demand liquid handling system which uses acoustic pressure waves to instigate the ejection of micro-droplets of liquid from an orifice at the base of a dispensing cartridge. The system can be used to dispense substances such as: proteins; antibodies; nano-materials; crystals; living cells; bacteria; DNA; and a wide variety of organic and inorganic reagents . Unique to this technology is the use of inexpensive disposable dispensing cartridges, which completely avoid cross-contamination risks and support quick fluid changeover. The volume of the micro-drops can be controlled to be in the range of approximately 10 pl to 120 pl (1pl = 10−¹² Litres) depending on the fluid properties and dispensing can take place on demand up to a frequency of 10 kHz.

Fig.1 shows a PolyPico dispensing head on the left and a dispensing cartridge on the right.

Depending on the characteristics of the fluid being dispensed, and the application, dispensing cartridges can be selected a range of orifice sizes (e.g. 30 um, 50 um, 70 um and 100 um). The technology works by introducing an acoustic pressure wave into the column of fluid in the dispensing cartridge. This pressure wave then propagates in the fluid and focuses at the orifice of the dispensing cartridge. This focused pressure wave is sufficient to break the surface tension at the orifice and eject a very precisely controlled, and very repeatable, pico-litre volume of fluid from the orifice. Each time an acoustic impulse is introduced into the fluid column a micro-drop is ejected. The volume is then calculated by the PolyPico system.

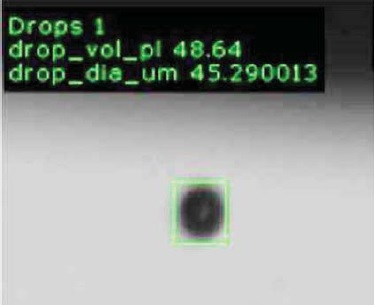

Fig. 2. An example of a micro-drop with a volume of 48.64 pl being dispensed [10].

This methodology for handling microcrystals in mother liquor for presentation to X-ray beams at both synchrotron and XFEL light sources is showing great promise. In its simplest format it offers an airborne goniometer with unlimited angular access for obtaining multiple angular rotations and their diffraction patterns. With the inclusion of the ability to unite multiple droplets and therefore instigate room temperature mixing, we have an excellent sample environment for time resolved experiments. As the reaction takes place in free space, there is no contamination between samples which in turn could be dosed with greater amounts of reagents. The other significant benefit for the system is the sample is stationary unlike with liquid jets allowing for reduction in waste and multiple angles and providing the potential to allow a structure being solved from a single crystal. This system particularly lends itself toward the study of Beta Lactamases as it can suspend the protein crystals, add reagents, initiate mixing and rotate to collect angular data, all at room temperature. It also offers the potential to reduce handling quantities down to pico-litre slurries of crystals.”

Access to the full article can be found here: http://www.sensorsportal.com/HTML/DIGEST/P_2938.htm

For more information on PolyPico’s acoustic dispensing technology contact info@polypico.com

Related Posts

Revolutionising Fluid Dispensing with Microdrop Technology – EU Startup News Feature

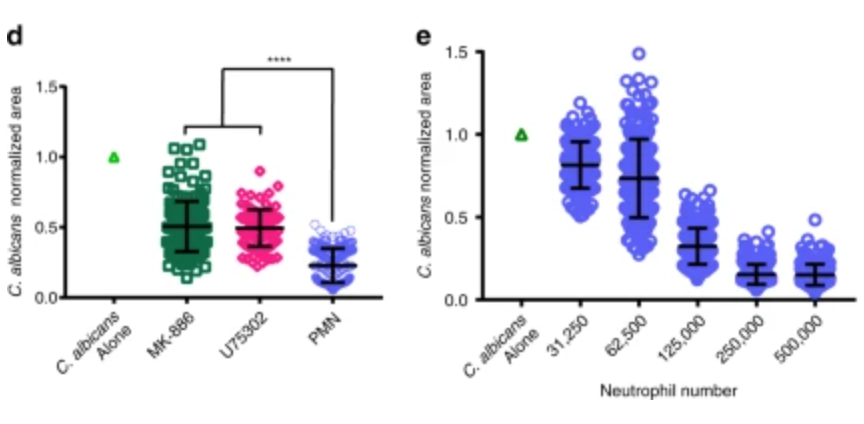

Polypico systems, used in breakthrough Neutrophil research