If you’re working in a field where precision fluid handling is critical—and you’re struggling to find an effective solution—you’ve come to the right place.

At PolyPico Technologies, we specialize in ultra-precise, non-contact micro dispensing systems that deliver exceptional performance down to the picoliter scale. Whether you’re in biotechnology, diagnostics, advanced materials, or microelectronics, this guide will walk you through the fundamentals of micro dispensing and how our technology is solving complex fluid management challenges across industries.

Let’s dive in.

What Is Micro Dispensing Technology?

Micro dispensing refers to the controlled delivery of very small volumes of liquids or pastes, typically in the picoliter to microliter range. At PolyPico, we enable our customers to accurately deposit even single droplets—as low as 10 pL—with repeatability and zero waste.

This technology is fundamental in any domain where precision, speed, and reliability are non-negotiable. It’s commonly applied in:

-

Pharmaceutical and biomedical R&D

-

Advanced electronics assembly

-

Diagnostics and biosensor fabrication

-

Additive manufacturing and bioprinting

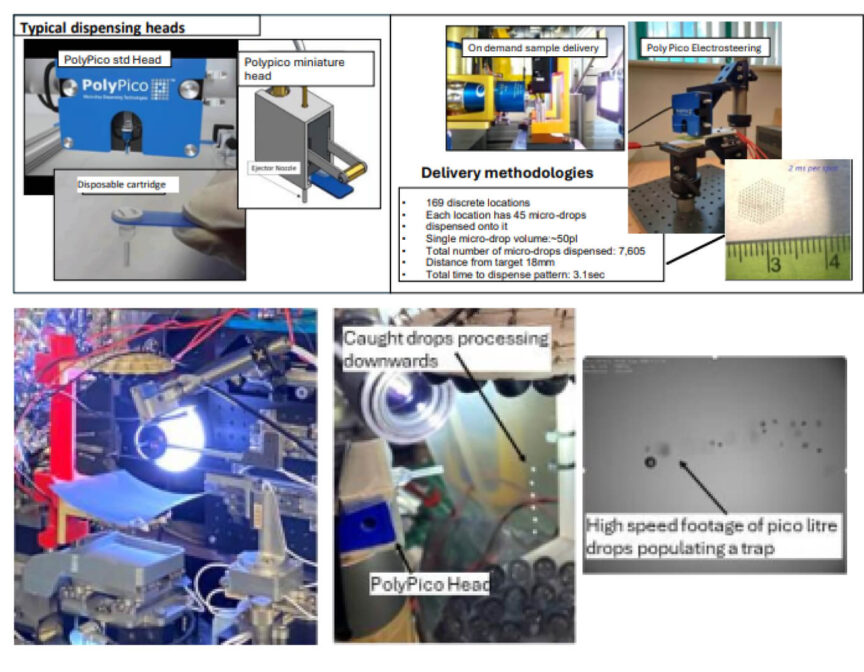

Our advanced systems integrate piezo-based actuation, fully digital control, and interchangeable fluid cartridges, offering best-in-class performance with maximum flexibility.

Types of Micro Dispensing Systems

There’s no one-size-fits-all in precision dispensing. That’s why understanding the various dispensing methods is essential for choosing the right solution for your application. Here’s a breakdown of common micro dispensing technologies:

1. Jetting Systems

Jetting systems rely on pressure pulses to eject droplets at high speeds. While effective for certain industrial applications, they can struggle with clogging, overspray, and fluid inconsistency—especially when working with delicate biomaterials.

2. Piezoelectric Dispensing (Our Core Technology)

At PolyPico, we use piezo-actuated micro dispensing, where mechanical deformation of a piezoelectric element causes fluid to eject precisely and repeatably—without physical contact or contamination risk. This allows for dispensing picoliter to nanoliter droplets of a wide range of fluids, including:

-

DNA/RNA solutions

-

Proteins and enzymes

-

Organic solvents

-

Live cell suspensions

3. Time-Pressure Dispensers

These systems apply timed air pressure to dispense fluid volumes. Though useful in general industrial processes, they lack the precision required for high-end microfluidic applications and often result in inconsistent delivery.

4. Auger Valve Systems

Ideal for high-viscosity pastes, such as solder or epoxies, these systems use a rotating screw mechanism. However, they are less suitable for applications requiring ultra-low-volume precision or delicate biological reagents.

5. Needle Dispensing Systems

Needle-based systems work via contact, which increases the risk of contamination, sample loss, or substrate damage. These are best used for less sensitive industrial processes with larger volume tolerances.

At PolyPico, we prioritize non-contact dispensing for unmatched accuracy, sterility, and repeatability.

Applications of Micro Dispensing Technology

Micro dispensing is a cornerstone for next-generation manufacturing and scientific innovation. Below are some of the key industries we serve:

1. Pharmaceuticals & Life Sciences

-

Personalized medicine through precision drug delivery

-

High-throughput screening for drug discovery

-

Microarray and biosensor fabrication

-

Bioprinting of cells and biomaterials

2. Diagnostics & Healthcare

-

Precise reagent placement for lab-on-a-chip and point-of-care devices

-

DNA, protein, and antibody spotting

-

Integration into microfluidic diagnostic platforms

3. Electronics & Semiconductors

-

Deposition of adhesives, underfills, and coatings

-

Assembly of MEMS, PCBs, and optoelectronic components

-

Solder paste delivery for miniaturized devices

4. Aerospace & Automotive

-

Fluid sealing, thermal coatings, and bonding materials

-

Automated application of high-performance adhesives

-

Reducing component weight via material-efficient dispensing

5. Consumer & Industrial Goods

-

Fragrance, ink, or pharmaceutical cartridge filling

-

Cosmetic and nutraceutical micro-dosing

-

High-volume packaging lines that require sub-microliter precision

Why Choose Micro Dispensing? The PolyPico Advantage

Adopting micro dispensing offers far more than just precise volume control. Here are the major advantages:

✅ Unmatched Precision

Deliver consistent droplets as small as 10 pL with tight tolerances, ensuring product quality and reproducibility.

✅ High Efficiency

Our systems are automated and digitally controlled, minimizing downtime and streamlining fluid handling.

✅ Zero Waste Technology

With no dead volume, our systems make the most out of even your most expensive or limited samples.

✅ Unparalleled Flexibility

Our modular design allows for quick reconfiguration to handle a broad range of viscosities and fluid types—all with the same platform.

✅ Miniaturization Support

Ideal for high-density biochips, portable diagnostics, and lightweight electronics that require tiny, accurate dosing.

✅ Customization & Scalability

From benchtop to batch production, PolyPico supports your workflow at every stage—tailored to your needs.

Final Thoughts from PolyPico

Micro dispensing is no longer optional—it’s essential. Whether you’re designing biosensors, optimizing drug formulations, or building the next generation of electronics, precision dispensing is central to success.

At PolyPico Technologies, our mission is to empower researchers, engineers, and manufacturers with innovative, reliable, and user-friendly solutions that scale with your ambitions.

To schedule a 30-minute demo click here:

https://lnkd.in/e2Aw_iQS

Related Posts

The application of acoustics for sample manipulation and delivery at X-Ray Light Sources

Precision and Speed: Why Choose One When You Can Have Both?