Printing Better Drugs for Better Results

Published by Jessica Burdg

Three-dimensional (3-D) printing is essentially layered manufacturing. What varies from project to project, of course, is exactly what is being layered and why. Used in a variety of scientific and creative endeavors around the globe, the technology—developed in the 1980s—is not a new one. Of particular note, however, are the advancements professionals in the pharmaceutical and drug development industries continue to make using this technology that benefit researchers, consumers and patients.

How it works

The process of 3-D printing may seem like a difficult one, but it’s not as complicated as it sounds, explains David Prawel, Director of the Idea-2-Product 3D Printing Laboratory at Colorado State Univ., in an interview with Laboratory Equipment.

The printer head goes back and forth, like your typical office printer. The difference, however, lies in both the printing materials and the scientific possibilities. Layer by layer, 3-D printers build objects using everything from simple plastics to living cells. For many projects, CAD (computer aided design) software is employed to design and structure the end result.

What if you could print stem cells to build organs for pharmaceutical testing? What if you could use a 3-D printer to help determine the success of a particular cocktail of chemotherapy drugs on a patient before administering them, allowing you to give the patient only the medication that would work best given his/her anatomy? What if you could create a new type of pill that is easier to take and delivers results faster? What if you could build a new laboratory pipetting system that is specific to your work, thereby increasing your efficiency and allowing you to help more people with your discoveries? With 3-D printing, you can.

“In your mind, change the concept of print and generalize the concept of printing,” said Prawel. “Printing could be spraying, extruding or melting.” In any of those circumstances, layer-by-layer, you’re building something.

Pharmaceutical testing

A 3-D printer can be used to print and layer stem cells, opening innumerable doors for researchers testing the drug effects of particular pharmaceuticals. Using this technology, those on the bench can print cells to form functional human organs upon which new pharmaceuticals can be tested. In some cases, this can shorten the time required for clinical trials and also reduce the inherent risks and liabilities associated with testing new drugs.

In order to print organs from stem cells using a 3-D printer, the cells must be contained in specific temperature-controlled solutions and printed down onto surfaces conducive to their survival, notes Richard Parker, President of REPCO Development Technologies.

“In order to make a 3-D structure from the cells [such as a new organ], we need to get something down first—typically referred to as a scaffolding—which is a bio-compatible substance the cells can adhere to,” Parker told Laboratory Equipment. Often, hydrogels are employed for this purpose.

At REPCO Development Technologies, a company providing scientists with recommended methodologies based on their particular fluidity applications, Parker has seen many unique uses for 3-D stem cell printing.

At the Wake Forest Institute for Regenerative Medicine, for example, Parker worked with a team that was successful in taking a bladder from a patient and decellurizing it, leaving only the fibrous structure. Using a 3-D printer to reproduce stem cells, the researchers were able to recellurize the organ to create a new bladder for a patient awaiting transplant.

Even if the researcher’s intent is not to formulate or receullurize a brand new organ using a 3-D printer, simply printing stem cells into groups can aid in the pharmaceutical testing process as well. This holds especially true for chemotherapy drug testing. With all of the different drugs and combinations of drugs used to treat cancer patients, it is a trial and error process to determine what course of treatment is the most effective.

“Today, some companies will harvest a cancer patient’s cells and send them to a lab. There, they’ll be incubated and separated. [Using 3-D printing to reproduce certain groups of cells], they can test different chemotherapy drugs on each group of cells to see what provides the best results without subjecting the patient to multiple compounds that may be ineffective,” said Parker.

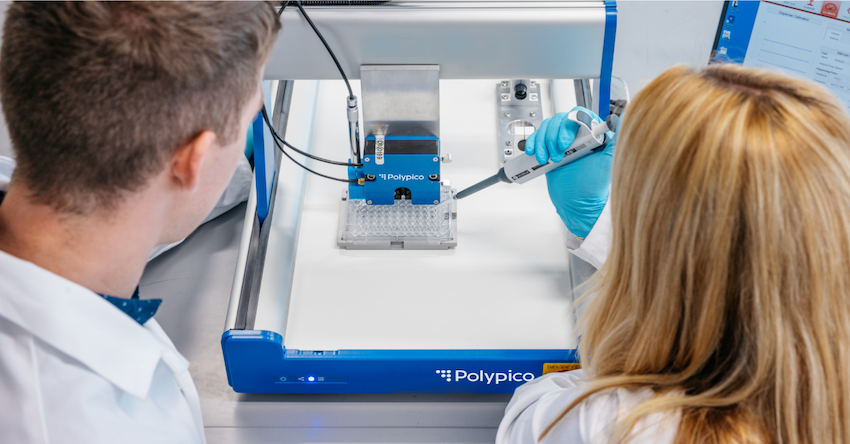

Alan Crean, CEO of Poly Pico Technologies, Ltd., agrees that the possibilities for stem cell printing to benefit the pharmaceutical industry are numerous. His company has developed the PolyPico printing system, which is a dispenser particularly designed to print stem cells, proteins, antibodies and DNA at a picoliter to nanoliter volume range.

The PolyPico printing system, identified as a powerful R&D tool for life science work, allows scientists to fill the dispensing cartridges with their material of choice. The cartridges are disposable, preventing cross-contamination.

As an important addition to the technology, Poly Pico dispensers can also print the scaffolding on which the stem cells will be placed. This high-precision printing method can lay down live cells on the tiniest of intricacies, making it highly conducive to printing cells for organs, Crean explained.

“There is particular interest in the cloning of cells from a single cell and testing various pharmaceuticals against individual groups of cells from this cloned population, which are essentially identical,” said Crean. “There are other potential benefits such as printing various different organ cells in a single well so that the interaction of pharmaceutical with a particular organ can be assessed. Also, you can observe what effects byproducts produced by this primary interaction may have on other organs.”

Drug development

Besides printing specific stem cells for organ creation and testing, 3-D printing can also be used in drug development.

Jennifer Zieverink, Senior Director of Alliance Management at Aprecia Pharmaceuticals, says the 3-D printing platform has a definite place in drug development. Her company, in fact, has pioneered its use there.

By thinly layering powdered medication and strategically placing particular fluids into the forms to produce microscopic bonds without using compression or molds, Aprecia uses 3-D printing to produce drugs on the Zip Dose platform.

What’s interesting about 3-D printing-based drug development platforms like Zip Dose is that these medications dispense more rapidly, making them easier to take and better at masking unpleasant tastes.

“The 3-D manufacturing platform yields highly porous structures even at high loading and high doses of drug,” Zieverink told Laboratory Equipment. “If approved and commercialized, our Zip Dose product candidates will help serve patients who need medicines that are easier to take and caregivers—including physicians and nurse practitioners—who want medicines that are easier to administer.”

Speed and efficiency

In addition to changing how medications are developed, 3-D printing can also change how laboratories function in terms of efficiency, said David Prawel of Colorado State Univ.

“There are many applications for the drug industry beyond what you would automatically picture,” said Prawel. “People print customized laboratory gadgets for everything, including pipetting and automatic sampling. They can build custom devices that increase speed and efficiency.”

Universal procedures, such as pipetting, are performed by researchers in laboratories working across a variety of disciplines, including those in pharmaceutical and drug development. Work on the bench can be done more efficiently because of a piece of labware specifically printed to save precious time—and that bodes well for both scientists and consumers.

Prawel’s knowledge of the industry is matched by his enthusiasm for the 3-D printing technology and what it can mean for scientific advancements.

“I’ve been enamored with 3-D technology since I started writing software,” said Prawel. “It’s exciting because of all the things it has done to help people. I can work in a technology that is fun, challenging and really helps people. That gets me up in the morning.

Source: http://www.laboratoryequipment.com/articles/2015/04/printing-better-drugs-better-results

http://www.laboratoryequipment.com/articles/2015/04/printing-better-drugs-better-results

Related Posts

Revolutionising Fluid Dispensing with Microdrop Technology – EU Startup News Feature

M3DLoC Open Day 24th June 2022